La automatización industrial consiste en el poder realizar de forma autónoma algún proceso que anteriormente se realizaba de forma manual. Lo anteriormente mencionado se realiza haciendo uso de sistemas de control y el monitoreo de los procesos por medio de sistemas programables que se instalan para que realicen un proceso automático ya programado.

Migracion de sistemas PLC

Podemos hacer tus migraciones de entre las diferentes marcas de PLC mas reconocidas, como por ejemplo Siemens , Allen Bradley , Schneider, etc.

Automatizacion de Procesos

Utiliando nuestra marca estrella B&R Automation, podemos implmentar controles en sistemas existentes antiguos o algun proyecto nuevo en curso.

Servicios de Diagnostico

Realizamos visitas de diagnostico de sistemas automatizados, electricos, electronicos y neumaticos en calidad de emergencia o visita normal programada.

Integracion de sistemas e implementacion de redes industriales

Realizamos integracion de sistemas actuales o nuevos, interconexion entre equipos automatizacines, equipos de medicion, instruamentos etc. usando las redes de comunicacion industral mas rapidas en el mercado.

Extraccion de datos via Servidor/Cliente – OPC UA

Extraccion de datos de proces dentro de PLC para utilziacion en area administrativa, a traves servicios servidor/cliente usando redes de alta velocidad Ethernet Industrial.

Vision con B&R Automation

Contamos con las camaras de vision integrada al PLC y todos sus accesorios, lentes, lamparas LED, etc.

Sistemas de Vision con Teledyne

Otro de nuestros productos estrella son las camaras para sistemas de vision Teledyne, para uso de sistemas de inspeccion sin depender de un PLC.

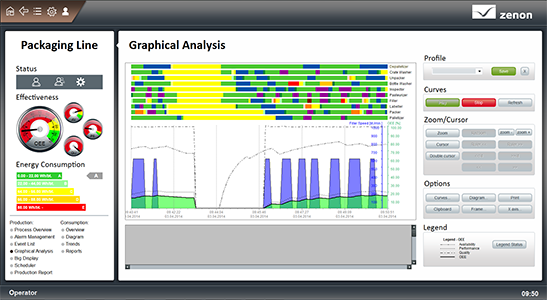

DISENO DE PANTALLAS DE OPERACION Y CENTROS DE MANDO

diseno personalizado a cada planta o proceso segun requerimientos.

MEDICION DE EFICIENCIA

El software esta capacitado para realizar tareas de medicion de eficiencia, OEE, etc.

Esta conexión remota se logra utilizando un software comúnmente llamado SCADA, el cual que se conecta a los controladores en su planta de producción. Con esto, se puede trabajar desde la recopilación de información de las líneas de producción, hasta el control de algún proceso que se pueda realizar de forma remota.

Toda esta información recopilada por el SCADA se almacena en un servidor para poder tener un control historico de sus procesos y llevar un mejor control de lo que sucede con cada línea de produccción. Todo esto puede ser utilizando para realizar mantenimientos preventivos y evitar fallas y paros en la producción.

Capacitaciones sobre los siguientes temas:

Programacion de PLC usando B&R Automation

Programacion de PLC usando Siemens (Tia Portal – Simatic Manager)

Programacion de PLC usando Allen Bradley

Curso de Automatismo para maquinas de embotellado como llenadoras, sopladoras PET, transporte de botellas, etc.

Contamos con personal altamente capacitado para dar soluciones a sus problemas. Se realizá un análisis de los procesos, se recomiendan soluciones para aumentar la eficiencia, todo esto mediante la automatización de diferentes áreas en su línea de producción, se trabajan estas soluciones para aumentar la capacidad y también la eficienca de su planta.

Existen diferentes forma de automatizar, y se pueden proveer diferentes soluciones dependiendo su necesidad.