B&R Key Advantages in the Plastics Industry

Increased Productivity: Automation reduces cycle times and minimizes human error. B&R systems, such as its servo motors and controllers, enable precise and rapid movements, increasing hourly output.

Energy Efficiency: B&R technology is designed to optimize energy consumption. Advanced motion control systems and energy recovery in servo motors help reduce operating costs and meet sustainability goals.

Improved Product Quality: The high precision and repeatability of B&R systems ensure consistent quality in plastic products, minimizing defects and material waste. This is crucial for applications requiring tight tolerances.

Flexibility and Modularity: B&R’s software and hardware architecture is modular. This means that companies can easily add or modify automation modules to adapt to new products or processes without having to replace the entire system. This flexibility is essential in a constantly changing industry.

Connectivity and Digitalization: B&R systems are compatible with Industry 4.0 technologies. They enable machine-to-machine (M2M) connectivity and integration with manufacturing management systems (MES) and enterprise resource planning (ERP), facilitating real-time data analysis for decision-making.

Safety and Reliability: B&R incorporates integrated safety features into its controllers and software, protecting both personnel and equipment. Its systems are known for their high reliability and low maintenance, reducing unplanned downtime.

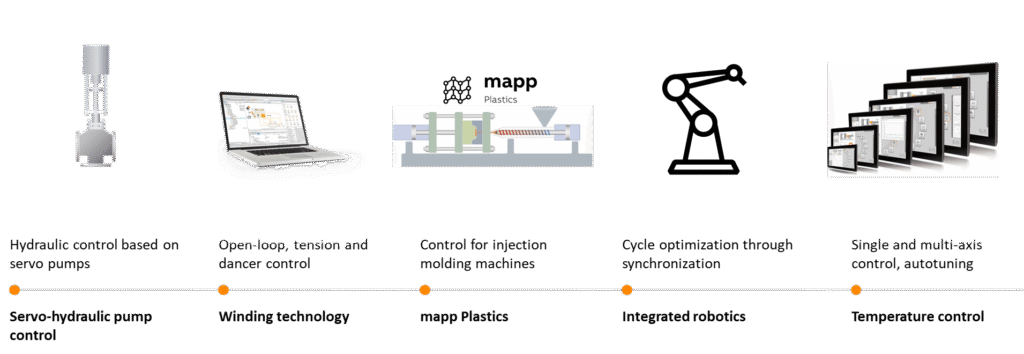

B&R key technologies

Want more information?

Contact us at email: sales.req@centratek.com