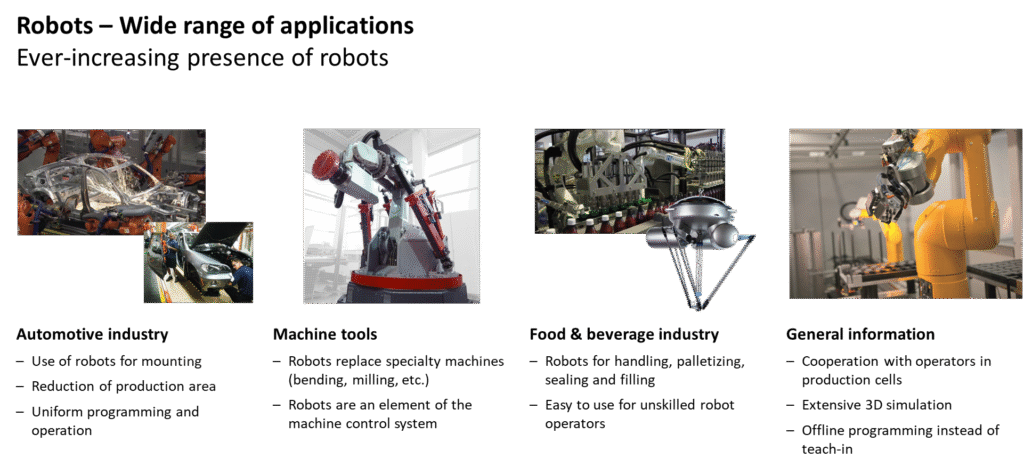

B&R Industrial Automation’s (a member of the ABB Group) Integrated Robotics Automation technology focuses on the complete integration of robotics with machine control into a unified automation architecture. This offers several key advantages for machine engineering and operation.

Key Features

B&R’s core philosophy is Machine-Centric Robotics (MCR), where the robot is no longer considered an independent system, but an integral and synchronized part of the machine.

- Total Integration

Unified Control: A single controller (B&R PLC) and engineering system (Automation Studio) are used for the entire machine, including motion control, machine logic, HMI (Human Machine Interface), and robot kinematics.

Less Hardware: By consolidating control, the need for dedicated robot controllers, interfaces, and wiring is reduced, simplifying design, maintenance, and increasing reliability.

Precise Synchronization: Enables microsecond-level synchronization between the robot, the machine’s motion axes (servo motors, transport systems such as ACOPOStrak or SuperTrak), and vision systems. This is crucial for high-speed, high-precision applications such as Pick & Place.

- Software and Tools

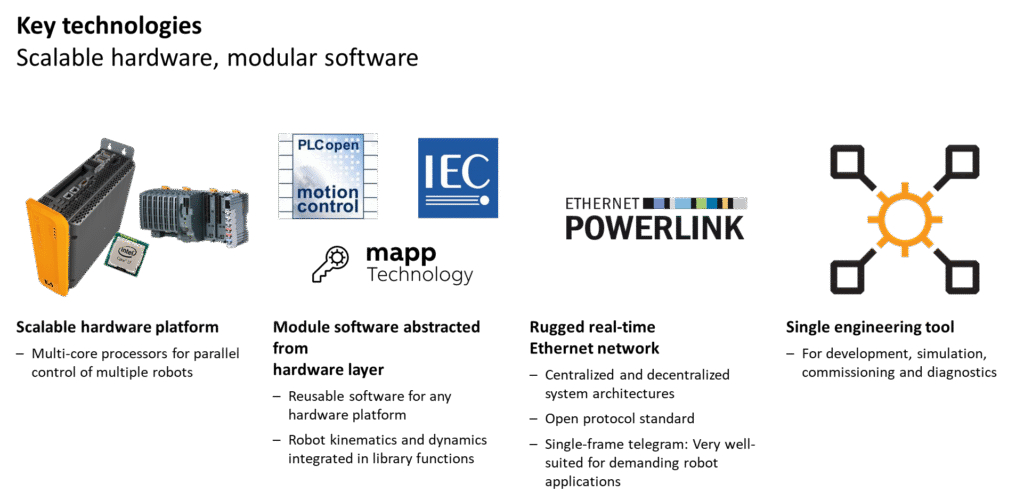

mapp Technology: B&R uses its modular software framework, mapp Technology, specifically the mapp Robotics library, which provides predefined function blocks and data structures for programming robots and kinematic models. This simplifies and accelerates development.

Simulation: Tools such as the B&R Scene Viewer and the MCR Performance Analyzer allow the creation of digital models (digital twins) of robot kinematics from CAD data. This facilitates virtual commissioning (simulation) of the application, performance analysis (pick rate), and detection of potential collisions before physical implementation.

Ease of Programming: The open platform and programming tools (including the Automation Studio Code extension) are designed to reduce the need for specialized robot programming knowledge.

Digital Twin and Simulation:

B&R’s digital twin allows the entire machine motion sequence, including robotics, to be simulated and optimized before the machine is physically built, accelerating development and reducing costs.

Flexibility and One-Stop-Shop Solutions:

By integrating robotics, B&R (ABB) positions itself as a one-stop-shop provider of complete industrial automation solutions, including control, drive, robotics, sensors, and software.

In short, the technology aims to make robotics integration much simpler, more precise, and more flexible for machine builders.

Want more information?

Contact us at email: sales.req@centratek.com